- GlideDining Carts

- Glide Cold Dining Carts

- Glide Heated Dining Carts

- Glide Ambient Dining Carts

- Glide Electrical MCB Station

- Glide Ambient Multideck

- Glide Ambient Multideck (Shutter)

- Glide Ambient Cupboard (Plain Top)

- Glide Cutlery Tray Pick Up Unit

- Glide Cashier Section

- Glide Waste Clearing Trolley

- Glide Low Height Tray Pick Up Stand

- Glide 45° & 90° Corner Infill Units

- Glide Twin Ambient Plate Dispenser

- Glide Sanitising Dispenser Unit

- Glide Cold Dining Carts

- Drop InDisplays

- MerchandisersStand Alone

- PatisseriesStand Alone

- FabricationBespoke

- BackbarModules

- ServeryCounters

- GalleryCED

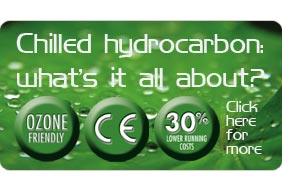

- HydrocarbonRefrigeration

- HygieneSolutions

- CED Sanitiser Posts (Electronic/ Pump Dispenser)

- CED Guide Posts

(& Braided Ropes/

Hooks)

- CED Retractable Tape Barrier Posts

(Red/Black Belt)

- CED Elec. Sanitiser/

Retractable Tape

Barriers (Wall Mounted)

- Tournus Sanitiser Post (Pump Dispenser) Alcohol Gel

- Tournus Mobile Sanitiser Unit

(Pedal Operated)

- CED Sanitiser Posts (Electronic/ Pump Dispenser)

- StorageEquipment

- Basket Rack & Tray Dolley Range

- Euronorm & GN Container Trolley Range

- Self Help Tray Storage Trolley Range

- Racking : Aluminium & Polypropylene Shelving

- Utensil & Bakery Equipment Storage

- Basket / GN Container Storage Trolley Range

- Kitchen Storage & Preparation Trolleys

- Transport, Meat Hook & Laboratory Trolleys

- Waste Bag Holders & Bins

- Catering Storage Cupboards

- Bread Preparation Unit Range

- Wall Mounted Shelving Range

- Waste Management (Sorting Units & Tables)

- Basket Rack & Tray Dolley Range

- ServingEquipment

- Holding / Re-heatingEquipment

- WashingEquipment

- SterilizingEquipment

- QuickService

- NewProducts

FAQs

High Quality Digital Control Panel Technology.

- All displays use Dixcell control system, to ensure reliable electrical operation of all displays. High level temperature recording accuracy is via digital temperature probes.

- Standard ‘tamper proof’ temperature control facility prevents customer interference/unauthorised operator adjustment if required.

- All displays can be connected to Modbus RTU & Dixell network store food monitoring systems.

- If condensing unit breakdown occurs from overheating, (due to high ambient temperatures, insufficient airflow or irregular cleaning), the control panel switches condensing unit off before long term damage occurs.

(Control panel automatically resets the condensing unit to switch back on when it has cooled down. After 5 attempts, control panel switches the unit off, The unit then has to be reset manually. This function stops condensing unit from becoming irreparably damaged, when exposed to continual high ambient conditions). - The Dixell Control system used helps limit high cost and/or chargeable service calls to customer/end user (as described above)

regards

admin

Condensate Water Removal By Integral High Efficiency, Reduced Energy Evaporation Tray.

A high efficiency, reduced energy evaporation tray is also fitted to all cold displays. A float switch turns a high wattage heating element on and off, depending on the amount of water in the tray.

- Element can remove up to 1.1 litre of water per hour.

- Yearly running costs reduced as less electricity use.

- Capacity to operate in higher than normal ambient temperatures and higher humidity levels, without excess water flooding.

- Reduces the running temperature in the condensing unit cradle area – extends the life of the condensing unit, when in constant high ambient temperature sites.

regards

admin

Coil Size Use – Chilled Displays

Larger evaporator coil used delivers far better chilling performance than drop in competitors. In high ambient sites this helps maintain food core at or below legal max. (8 deg C) where smaller coils cannot produce same cold air holding temperatures.

regards

admin

Heated Displays Feature ‘Touch Safe’ Gantry. (less than 40 deg c surface temperature)

User friendly design to limit possibility of clinical burn injury on any heated units.

regards

admin

Electrical & Refrigeration Test Reports Provided With Each Model.

For inclusion in project Health & Safety file documentation if required

regards

admin

Investment In Automated Hydrocarbon Refrigeration Charging/Testing/Leak Detection Station.

Hydrocarbon refrigeration, charging/testing/leak detection station for chilled units, comprising system evacuation, pressure testing, hydrogen leak testing, automated refrigeration charging levels. To ensure consistent leak free quality refrigerated performance of each chilled drop in display.

regards

admin

Investment In Automated Electrical Testing.

Test station comprising earth continuity, high voltage flash, insulation resistance, load and soak, to ensure each drop in display leaves the factory electrically sound.

regards

admin

Control Box PCB Board Programming Via ‘Hot Keys’,

No manual programming. Prevents programming errors, ensures reliable control equipment & consistent field performance.

regards

admin

Independent Chilled Display Performance Testing.

Independent product testing by Brunel University, determining maximum ambient humidity levels CED chilled displays can perform in. (27deg C 55% relative humidity – side draught 0.2 m/sec.)

regards

admin

Manufacturers assurance that products meet current legislation/safety related directives and all sourced components used in manufacture are of the highest quality. Hydrocarbon range included.

regards

admin

High Quality Digital Control Panel Technology.

- All displays use Dixcell control system, to ensure reliable electrical operation of all displays. High level temperature recording accuracy is via digital temperature probes.

- Standard ‘tamper proof’ temperature control facility prevents customer interference/unauthorised operator adjustment if required.

- All displays can be connected to Modbus RTU & Dixell network store food monitoring systems.

- If condensing unit breakdown occurs from overheating, (due to high ambient temperatures, insufficient airflow or irregular cleaning), the control panel switches condensing unit off before long term damage occurs.

(Control panel automatically resets the condensing unit to switch back on when it has cooled down. After 5 attempts, control panel switches the unit off, The unit then has to be reset manually. This function stops condensing unit from becoming irreparably damaged, when exposed to continual high ambient conditions). - The Dixell Control system used helps limit high cost and/or chargeable service calls to customer/end user (as described above)

regards

admin

Condensate Water Removal By Integral High Efficiency, Reduced Energy Evaporation Tray.

A high efficiency, reduced energy evaporation tray is also fitted to all cold displays. A float switch turns a high wattage heating element on and off, depending on the amount of water in the tray.

- Element can remove up to 1.1 litre of water per hour.

- Yearly running costs reduced as less electricity use.

- Capacity to operate in higher than normal ambient temperatures and higher humidity levels, without excess water flooding.

- Reduces the running temperature in the condensing unit cradle area – extends the life of the condensing unit, when in constant high ambient temperature sites.

regards

admin

Coil Size Use – Chilled Displays

Larger evaporator coil used delivers far better chilling performance than drop in competitors. In high ambient sites this helps maintain food core at or below legal max. (8 deg C) where smaller coils cannot produce same cold air holding temperatures.

regards

admin

Heated Displays Feature ‘Touch Safe’ Gantry. (less than 40 deg c surface temperature)

User friendly design to limit possibility of clinical burn injury on any heated units.

regards

admin

Investment In Automated Hydrocarbon Refrigeration Charging/Testing/Leak Detection Station.

Hydrocarbon refrigeration, charging/testing/leak detection station for chilled units, comprising system evacuation, pressure testing, hydrogen leak testing, automated refrigeration charging levels. To ensure consistent leak free quality refrigerated performance of each chilled drop in display.

regards

admin

Investment In Automated Electrical Testing.

Test station comprising earth continuity, high voltage flash, insulation resistance, load and soak, to ensure each drop in display leaves the factory electrically sound.

regards

admin

Control Box PCB Board Programming Via ‘Hot Keys’,

No manual programming. Prevents programming errors, ensures reliable control equipment & consistent field performance.

regards

admin

Independent Chilled Display Performance Testing.

Independent product testing by Brunel University, determining maximum ambient humidity levels CED chilled displays can perform in. (27deg C 55% relative humidity – side draught 0.2 m/sec.)

regards

admin

Manufacturers assurance that products meet current legislation/safety related directives and all sourced components used in manufacture are of the highest quality. Hydrocarbon range included.

regards

admin