- GlideDining Carts

- Glide Cold Dining Carts

- Glide Heated Dining Carts

- Glide Ambient Dining Carts

- Glide Electrical MCB Station

- Glide Ambient Multideck

- Glide Ambient Multideck (Shutter)

- Glide Ambient Cupboard (Plain Top)

- Glide Cutlery Tray Pick Up Unit

- Glide Cashier Section

- Glide Waste Clearing Trolley

- Glide Low Height Tray Pick Up Stand

- Glide 45° & 90° Corner Infill Units

- Glide Twin Ambient Plate Dispenser

- Glide Sanitising Dispenser Unit

- Glide Cold Dining Carts

- Drop InDisplays

- NEW Scenic Hot / Cold Deli Drop In Display Range

- Kubus Cold Drop In Display Range

- Kubus Hot Drop In Display Range

- Kubus Ambient Drop In Display Range

- Kubus Drop In Display Options

- Designline Cold Drop In Display Range

- Designline Hot Drop In Display Range

- Designline Ambient Drop In Display Range

- Designline Drop In Display Options

- NEW Scenic Hot / Cold Deli Drop In Display Range

- NEW Drop InPatisseries

- MerchandisersStand Alone

- NEW PatisseriesStand Alone

- FabricationBespoke

- BackbarModules

- ServeryCounters

- GalleryCED

- HygieneSolutions

- CED Sanitiser Posts (Electronic/ Pump Dispenser)

- CED Guide Posts

(& Braided Ropes/

Hooks)

- CED Retractable Tape Barrier Posts

(Red/Black Belt)

- CED Elec. Sanitiser/

Retractable Tape

Barriers (Wall Mounted)

- Tournus Sanitiser Post (Pump Dispenser) Alcohol Gel

- Tournus Mobile Sanitiser Unit

(Pedal Operated)

- CED Sanitiser Posts (Electronic/ Pump Dispenser)

- StorageEquipment

- Basket Rack & Tray Dolley Range

- Euronorm & GN Container Trolley Range

- Self Help Tray Storage Trolley Range

- Racking : Aluminium & Polypropylene Shelving

- Utensil & Bakery Equipment Storage

- Basket / GN Container Storage Trolley Range

- Kitchen Storage & Preparation Trolleys

- Transport, Meat Hook & Laboratory Trolleys

- Waste Bag Holders & Bins

- Catering Storage Cupboards

- Bread Preparation Unit Range

- Wall Mounted Shelving Range

- Waste Management (Sorting Units & Tables)

- Basket Rack & Tray Dolley Range

- ServingEquipment

- Holding / Re-heatingEquipment

- WashingEquipment

- SterilizingEquipment

- QuickService

- NewProducts

About Us

Cutting -Edge Production Facilities.

Cutting -Edge Production Facilities.

Powerful manufacturing alliances with leading design houses, equipment hirers and distributors allow CED to deliver on many sizes of order, from a single one-off dish wash table to the latest in energy efficient refrigerated drop in food displays.

Whatever the project, CED is wholly committed to providing the best quality solution at a competitive price and within a time-scale that exceeds our customers’ highest expectations.

At CED’s modern 50,000 sq ft factories in Blackburn, Knowsley and Kent we provide a rapid in-house design, manufacturing and assembly service, assured by line side components and an efficient multi-shift operational system.

Production Capabilities.

CED employ a diverse & talented workforce whose skill set allows us to provide:

* Stainless steel fabrication, bespoke bar & servery counter manufacture & installation.

* Stainless steel fabrication, bespoke bar & servery counter manufacture & installation.

* Woodworking and solid surface material production.

* Electrical assembly.

* Refrigeration product assembly.

* High grade welding and polishing operations for engineered and aesthetic products.

* CED are a fully accredited Corian™ & LG Hi-Macs™ fabricator.

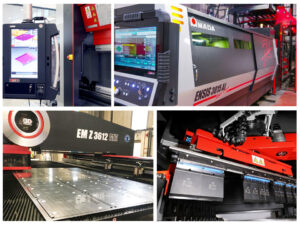

Production Machinery.

CED operates using state-of-the-art tooling and machinery to ensure an exceptional standard of finished product.

* Fully-automated CNC Amada EMZ3612MII sheet metal punching with automated MP3015 Sheetcat loading system.

* Fully-automated CNC Amada EMZ3612MII sheet metal punching with automated MP3015 Sheetcat loading system.

* Fully-automated CNC Amada ENSIS 3015 3KW fibre laser system with automated ASLUL 10 station sheet tower.

* Offline programmed CNC Amada HG1003-ATC press brake with automatic tool changer.

* Metal folding capacity provided by a further five advanced folding machines.

* Full TIG welding with dedicated polishing bays.

* Carpentry/joinery shops with CNC table routers for processing solid woods, MDF, laminates, solid surfaces such as Corian.™

* CNC edge banding machines with automated conveyor, for mass production of door and fascia panel edging.