- GlideDining Carts

- Glide Cold Dining Carts

- Glide Heated Dining Carts

- Glide Ambient Dining Carts

- Glide Electrical MCB Station

- Glide Ambient Multideck

- Glide Ambient Multideck (Shutter)

- Glide Ambient Cupboard (Plain Top)

- Glide Cutlery Tray Pick Up Unit

- Glide Cashier Section

- Glide Waste Clearing Trolley

- Glide Low Height Tray Pick Up Stand

- Glide 45° & 90° Corner Infill Units

- Glide Twin Ambient Plate Dispenser

- Glide Sanitising Dispenser Unit

- Glide Cold Dining Carts

- Drop InDisplays

- NEW Scenic Hot / Cold Deli Drop In Display Range

- Kubus Cold Drop In Display Range

- Kubus Hot Drop In Display Range

- Kubus Ambient Drop In Display Range

- Kubus Drop In Display Options

- Designline Cold Drop In Display Range

- Designline Hot Drop In Display Range

- Designline Ambient Drop In Display Range

- Designline Drop In Display Options

- NEW Scenic Hot / Cold Deli Drop In Display Range

- NEW Drop InPatisseries

- MerchandisersStand Alone

- NEW PatisseriesStand Alone

- FabricationBespoke

- BackbarModules

- ServeryCounters

- GalleryCED

- HygieneSolutions

- CED Sanitiser Posts (Electronic/ Pump Dispenser)

- CED Guide Posts

(& Braided Ropes/

Hooks)

- CED Retractable Tape Barrier Posts

(Red/Black Belt)

- CED Elec. Sanitiser/

Retractable Tape

Barriers (Wall Mounted)

- Tournus Sanitiser Post (Pump Dispenser) Alcohol Gel

- Tournus Mobile Sanitiser Unit

(Pedal Operated)

- CED Sanitiser Posts (Electronic/ Pump Dispenser)

- StorageEquipment

- Basket Rack & Tray Dolley Range

- Euronorm & GN Container Trolley Range

- Self Help Tray Storage Trolley Range

- Racking : Aluminium & Polypropylene Shelving

- Utensil & Bakery Equipment Storage

- Basket / GN Container Storage Trolley Range

- Kitchen Storage & Preparation Trolleys

- Transport, Meat Hook & Laboratory Trolleys

- Waste Bag Holders & Bins

- Catering Storage Cupboards

- Bread Preparation Unit Range

- Wall Mounted Shelving Range

- Waste Management (Sorting Units & Tables)

- Basket Rack & Tray Dolley Range

- ServingEquipment

- Holding / Re-heatingEquipment

- WashingEquipment

- SterilizingEquipment

- QuickService

- NewProducts

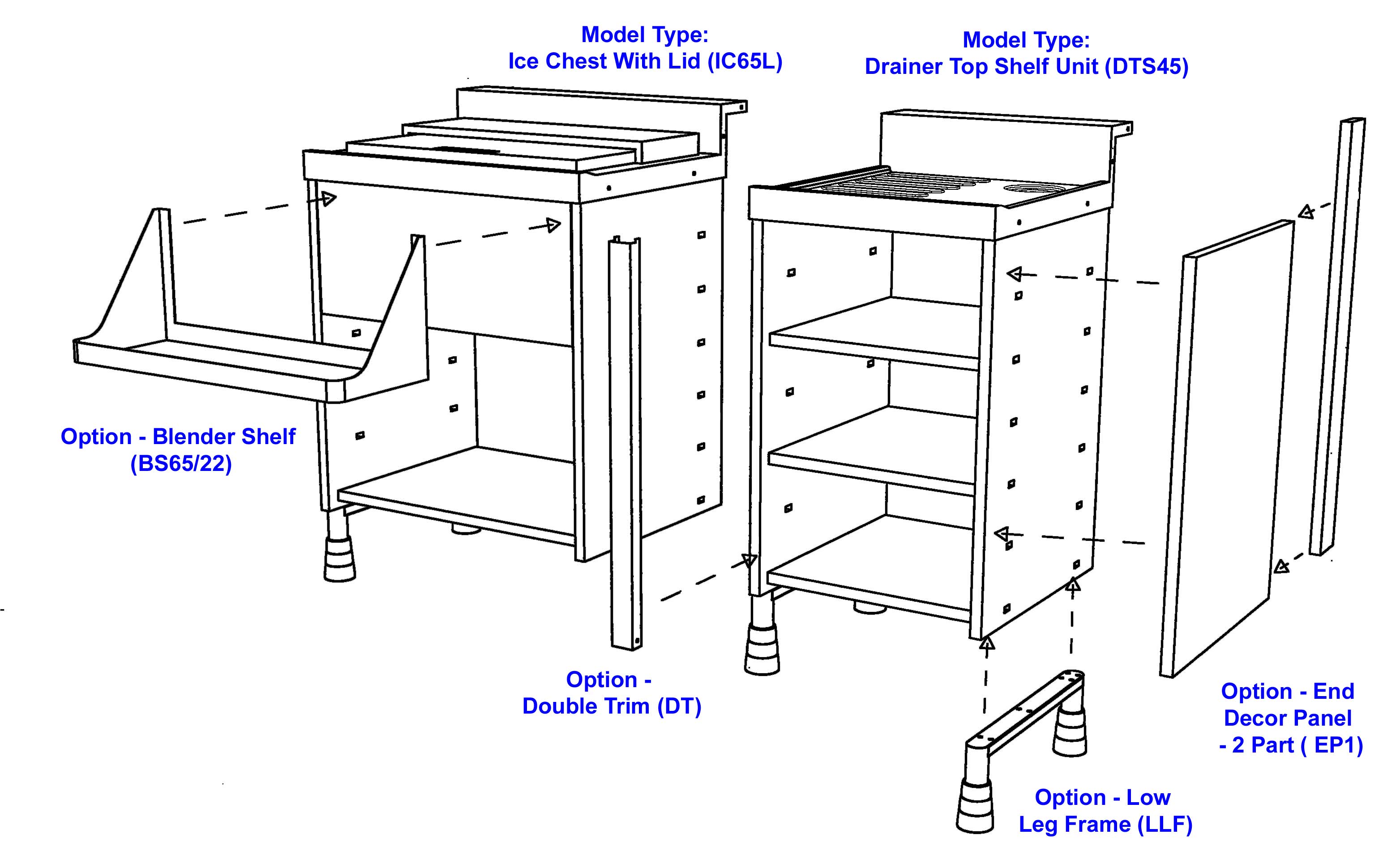

Backbar Bar System

Backbar – CED’s Modular Bar System.

Backbar – CED’s Modular Bar System.

CED’s Backbar range is a versatile, pre-engineered interconnecting modular bar system, produced from durable 0.9mm thick 430gd. steel panelwork, with 1.2mm thick 304 gd. s/steel worktops. Plain steel worktops and pressed steel drainer worktops allow for varied dry or wet area bar use. The units connect to form straight bar runs or can be faceted by the use of optional angled worktop infills.

The bases can be incorporated behind bespoke bar frontages and tops to provide the essential elements for a fully functioning bar servery area.

The Designline Backbar range consists of Shelving Units, Sinks & Wash Units, Storage Units, Ambient Storage and Accessories such as worktop angles or extensions.

Backbar Design Guidance.

Download and design your layout quickly and accurately with our electronic CAD drawings of the various modules (all located within the download section for each category. Most Backbar units come in standard sizes of 450, 650, 800 and 1000 mm long. Simply select the units and accessories required – using the stock codes shown.

Download and design your layout quickly and accurately with our electronic CAD drawings of the various modules (all located within the download section for each category. Most Backbar units come in standard sizes of 450, 650, 800 and 1000 mm long. Simply select the units and accessories required – using the stock codes shown.

Creating Facetted/ Angled Sections In The Design.

Curved or angled bar units are achieved by using a combination of :

A) Angled ‘infill’ worktop pieces fastened to the particular base unit. These are available in 10, 15, 20, 45 & 90 degrees (See AT10, AT15, AT20, CT45, CT90, CTW90).

B) Angled front unit ‘capping’ trims. The standard angled unit trim is 40mm wide at the front. Non-standard trims are available.

(See Angled Trim AT).

Combining ‘Bespoke’ Backbar Section Lengths In The Design.

Specific lengths of bar runs can be achieved using ‘bespoke’ versions (up to 1000 mm long) of :

C) Shelving Units (Standard units are PTS45, PTS65, PTS80, PTS100. A bespoke unit size is PTS85 i.e. 850mm long) or

D) Worktops. ( Standard units are PB45, PB65, PB80, PB100. A bespoke worktop size is PB85 i.e. 850mm long).

Loose Items Supplied With Each Backbar Base Unit.

Each Backbar base unit is supplied with one adjustable leg set (See LLF) and one double unit ‘capping’ trim (See DT).

Accessories Required With The Bar Design Ordered.

Additional Low Height Leg Set (see LLF) to end or void section per run

Additional High Leg Set (see HLF) to open end where void required

End Décor Panel – for each visible end panel of run (see EP1)

End Décor Panel – for each visible end panel of void section (see EP1)(Typically where bins are positioned)

Each base unit is supplied with one Low Height Leg Set (LLF)